YuYi

YuYi

Sep 11,2023

Sep 11,2023

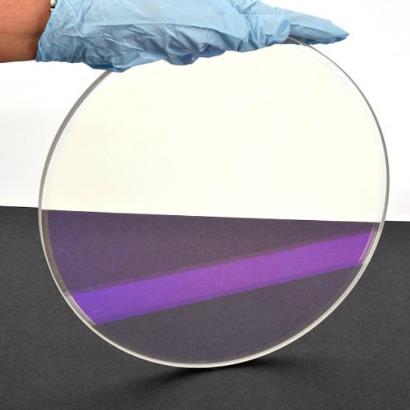

With the development of science and technology, making ceramics transparent is no longer a problem. At present, these polycrystalline materials with certain light transmittance are called transparent ceramics or optical ceramics in the industry. They are not only superior to traditional glass or resin optical materials in optical performance, but also have better strength, hardness, corrosion resistance and high temperature resistance. It has excellent performance in characteristics, so it can be used in extremely harsh environments or engineering design, such as the national defense industry, special industrial equipment, etc. It has great potential for future technological development.

Since Coble of GE Company in the United States developed the first translucent alumina ceramic in the early 1960s and opened up a new ceramic research direction, the development of transparent ceramics has been advancing at a rapid pace. Y2O3, Y2O3, MgO, MgAl2O4, Y3Al5O12, AlON, PLZT, CaF2 and other dozens of transparent ceramic materials.

Among them, yttrium oxide (Y2O3) has always been the focus of research in the field of transparent ceramics. It belongs to the cubic crystal system and has isotropic optical properties. Compared with the anisotropy of light-transmitting alumina, the image is less distorted, so it is gradually It is valued and developed by high-end lenses or military optical windows. The main characteristics of its physical and chemical properties are:

①High melting point, good chemical and photochemical stability, wide optical transparency range (0.23~8.0μm);

②At 1050nm, its refractive index is as high as 1.89, giving it a theoretical transmittance of more than 80%;

③Y2O3 has a large band gap from conduction to valence band that is large enough to accommodate the emission energy levels of most trivalent rare earth ions. It can effectively tailor the luminescence performance through doping of rare earth ions, thereby realizing its multifunctional application. change;

④ The phonon energy is low, and its maximum phonon cut-off frequency is approximately 550cm-1. The low phonon energy can suppress the probability of non-radiative transition and increase the probability of radiative transition, thus improving the luminescence quantum efficiency;

⑤Thermal conductivity is high, about 13.6W/(m·K). High thermal conductivity is extremely important for it as a solid laser medium material.

In essence, the preparation of Y2O3 transparent ceramics is not much different from that of other special ceramics. Most special ceramic preparation processes can be extended to the field of transparent ceramic preparation. However, the preparation of transparent ceramics is very important for every aspect of the process. Sensitive, especially the powder and sintering links.

The selection of high-quality powder is the key to obtaining high-performance transparent ceramics. The size, particle size distribution, shape and agglomeration state of the particles will directly affect the densification behavior of the ceramic during the sintering process and the microstructure of the sintered body. Ideal powder properties include:

①Submicron size, smaller particle size can obtain higher sintering driving force, but too fine powder is prone to agglomeration due to its high specific surface energy;

② The size distribution is narrow. The narrow size distribution can avoid the occurrence of differential shrinkage. When the particle size is unevenly matched, it will cause stress during the molding process and lead to uneven microstructure of the ceramic;

③The chemical purity is high. During the preparation process of transparent ceramics, the presence of impurities and impurities must be avoided, and the powder shall be prevented from being contaminated during the experiment;

④ The powder has good dispersion. The agglomeration of particles will reduce the specific surface area of the powder, reduce the sintering activity, and lead to inconsistent grain boundary mobility, which is not conducive to the densification of ceramics.

At present, there are two main methods for preparing Y2O3-based transparent ceramic powder: one is to use commercial high-purity powder as raw material, add a certain amount of sintering aids, use a ball milling process to obtain ceramic powder, and then sinter to prepare transparent ceramics; It uses wet chemical method/gas phase method to prepare Y2O3 ultrafine powder with high sintering activity, and then sinters it to obtain transparent ceramics without adding any sintering aids. The powder prepared in this way can be mixed at the atomic scale, effectively controlling the properties of the powder. It also has the advantages of narrow size distribution and low impurity content.

Sintering is an essential and key step in the ceramic preparation process. Different sintering technologies and sintering processes will have a huge impact on the microstructure of ceramics. To prepare transparent ceramics, it is necessary to make the bad body as completely densified as possible during the sintering process, and there should be no scattering centers such as pores inside, so as to improve the optical quality of the ceramics.

At present, the sintering methods reported for Y2O3-based transparent ceramics mainly include: hot press sintering, hot isostatic pressing sintering, vacuum sintering and hydrogen atmosphere sintering (dry hydrogen, wet hydrogen). The densification mechanism can be summarized as pure solid phase high temperature sintering, liquid Phase sintering/instantaneous liquid phase sintering, pressure assisted sintering and solid solution activation sintering. However, in order to improve the optical quality of Y2O3 transparent ceramics and reduce the sintering temperature, several sintering methods are often used in combination.