YuYi

YuYi

Oct 21,2023

Oct 21,2023

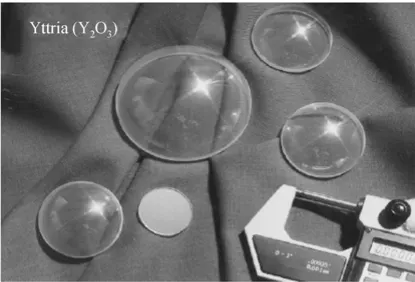

Yttrium oxide (Y2O3) has a cubic structure, high melting point, good chemical and photochemical stability, wide range of optical transparency, low phonon energy, and easy doping of rare earth ions. Its excellent plasma resistance makes it ideal for semiconductor processing equipment applications where particle contamination must be avoided, as it reduces equipment maintenance requirements, thereby increasing productivity.

Yttrium oxide transparent ceramic has excellent optical and thermal properties and is a functional material with high application value. It has potential applications in high-temperature windows, infrared hoods, luminescent media (flash, laser, and up-conversion luminescence), and semiconductor industries. value and has now become an alternative material to a single crystal.

High melting point, good chemical, and photochemical stability, a wide range of optical transparency (0.23~8.0μm);

At 1050nm, its refractive index is as high as 1.89, giving it a theoretical transmittance of more than 80%;

Yttrium oxide has a large heterogeneous band and effective tailoring of the valence band that is large enough to accommodate the emission energy levels of most trivalent rare earth ions, thereby achieving multifunctionality in its applications;

The phonon energy is low, and its maximum phonon cut-off frequency is approximately 550 cm-1. The low phonon energy can suppress the probability of non-radiative transition and increase the probability of radiative transition, thereby improving the efficiency of luminous lemons;

Thermal conductivity is high, about 13.6W/(m·K), and high thermal conductivity is extremely important as a solid laser cutoff material.

The above characteristics make yttrium oxide transparent ceramics have potential application value in high-temperature windows, infrared detection, luminescent media, and semiconductor industries.

The preparation of yttrium oxide transparent ceramics mainly involves two aspects: powder and sintering technology:

In terms of powders, some directly use commercial high-purity powders as raw materials, while others are powders synthesized using wet chemical methods, gas phase methods, etc.;

In terms of sintering, currently reported methods include hot pressing sintering, hot isostatic pressing sintering, vacuum sintering, and hydrogen atmosphere sintering (dry hydrogen, wet hydrogen). The densification mechanism can be summarized as pure solid phase high-temperature sintering, liquid phase sintering/ Instantaneous liquid phase sintering, pressure-assisted sintering, and solid solution activation sintering. In order to improve the optical quality of yttrium oxide transparent ceramics and reduce the sintering temperature, it is generally necessary to use a variety of sintering methods in combination.

Due to its excellent physical and chemical properties, yttrium oxide has been potentially developed in the following fields: missile infrared windows and domes, visible and infrared lenses, high-pressure gas discharge lamps, ceramic scintillators, and ceramic lasers.

High-pressure gas discharge lamp tube: Yttrium oxide has a cubic phase structure, isotropic optical properties, high chemical stability, and is resistant to corrosion by metallic sodium vapor and other metal halide vapors. Its use in the field of high-intensity gas discharge lamps has been studied Although there is progress in the direction of personnel efforts, there are still limitations such as technical costs and other factors before practical application and promotion.

Window materials: Materials with good optical transmission properties at 3~5 μm have important applications in the military field. Although researchers have successfully developed yttrium oxide transparent ceramics with better transmittance in the laboratory through various sintering processes, Since current commercial nanometer yttrium oxide powder contains many impurities, its optical properties cannot meet actual application needs.